|

|

|||||||||||||||||||||||||||

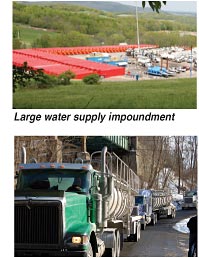

Stage Two: Natural Gas Site Mobile Water Treatment Systems  Our mobile FracPure™ system treats the contaminated water right at the drilling site! Our mobile FracPure™ system treats the contaminated water right at the drilling site!  FracPure™ Mobile Water Treatment Systems effectively remove all contaminants from frac water and return 80% of flowback, over 1 million gallons per well, into pure water distillate for re-use on the drilling sites. FracPure™ Mobile Water Treatment Systems effectively remove all contaminants from frac water and return 80% of flowback, over 1 million gallons per well, into pure water distillate for re-use on the drilling sites.The remaining 20% of the treated water is a highly concentrated salt brine, which is tested to ensure it is contaminant free. At this point, the brine is extremely high in chlorides and not yet ready for return to the environment. The brine is safely transported to our Crystallization Plant for the final phase of treatment which yields beneficial salt products and distilled water. The distilled water exceeds EPA drinking water standards and is safe to return to the water table. FracPure™ reduces trucking costs approximately 40% for natural gas companies. Natural gas companies spend a significant percentage of drilling completion costs on trucking in 4-6 million gallons of water per well to supply the hydraulic fracturing process, and trucking out over 1 million gallons of contaminated water for disposal. FracPure™ drastically cuts these costs, eliminating about 400 truckloads per site, by re-using 1 million gallons of treated water on-site and also reducing the volume of water for disposal by 1 million gallons. |

||||||||||||||||||||||||||||

The FracPure™ On-site Treatment The FracPure™ On-site Treatment Frac water is tested to determine the rate of processing. Chemical Precipitation Using a proprietary chemical treatment a solid is formed which removes heavy metals or Dissolved Solids from the water. The solids are de-watered and sent to a research laboratory to determine beneficial uses. Filtration Purified water continues through multiple stages of filtration to remove organics and Total Suspended Solids (TSS). The water is then sent to the concentrator. Evaporation The concentrator evaporates the brine down and yields purified distilled water for re-use on the drilling site, and a greatly reduced salt brine which is transported to the Crystallization plant to be processed into beneficial salt products and distilled water. On-site Testing Labs Integrated Water Technologies has state of the art testing labs onsite to ensure the concentrated brine meets the standards of processing for our Crystallization plant, and the distilled water from the treatment process is exceeding the EPA and all state regulatory groups’ recognized drinking water standard of 500 PPM (Parts Per Million). FracPure™ processed water averages less than 100 PPM and is safe to return to the environment. FracPure™ is the most environmental and cost effective solution for COMPLETE Frac Water Remediation. There are 3 ways to mobilize FracPure™ units to your natural gas site: 1. Fill out and submit a request for propsoal. Click here 2. Call 1-877-frac-H2--ZERO (877-372-2420) 3. Email info@integratedwatertech.com |

||||||||||||||||||||||||||||

| Integrated Water Technologies, Inc. 150 Clove Road, Suite 1101, Little Falls, NJ 07424 • Tel: 877-372-2420 • Fax: 973-890-8765 |

||||||||||||||||||||||||||||